FAQ

Find quick answers to the most common questions about our services, contracts, and support.

A DCA (Data Collection Agent) is a tool used to monitor printer devices and collect essential data such as page counters, consumable levels, error messages, serial numbers, and device models. This information is securely transmitted to a central cloud server (CPS), enabling proactive service, automated billing, and consumable management.

DCAs are non-invasive and read-only:

- They do not install drivers, push updates, or alter printer settings.

- They are suitable for high-security environments (e.g., financial, healthcare, military).

- They only collect operational data—never user data, print job content, or sensitive document info.

In Noetics:

- A DCA record links to a contract and customer, typically placing discovered devices into a PILOT contract.

- Devices marked with model = Discover are automatically updated with the correct model after the first DCA read.

- Monitoring begins once the DCA is connected to a contract.

Noetics currently integrates with the following DCA platforms:

- Nubeprint CPM (Noetics native DCA)

- PrintFleet

- EKM

- KPAX

- MPS Monitor

More integrations are planned as the platform evolves. We have the ability to take you with your current DCA if you want to. Our system can plug into the data collected by these "External DCAs" and store it directly in the Noetics platform.

CPM only collects non-sensitive operational data from printers. This includes:

- Serial number

- Model, MAC address and IP address

- Page counters

- Consumable levels

- Error messages displayed by the device

It does not collect user data, print jobs, document names, or printer settings. All data is read-only via SNMP and fully auditable.

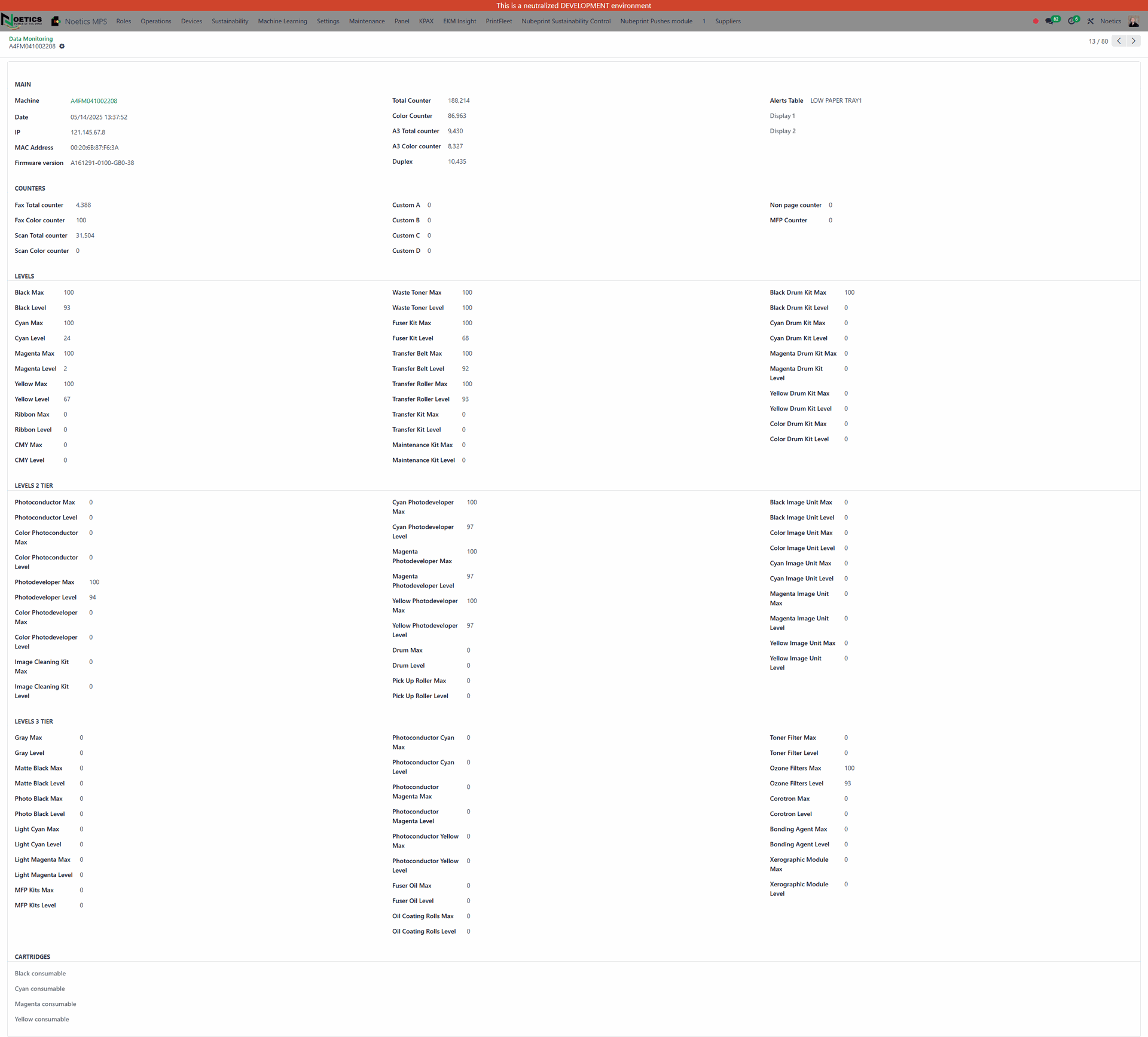

Here's how a Data Monitoring screen gets filled in for a single read in Noetics. To see it go to MPS > Devices > Data Monitoring (Data being filled in depends on printer and what the DCAs collect). Right click and open image in new tab to see

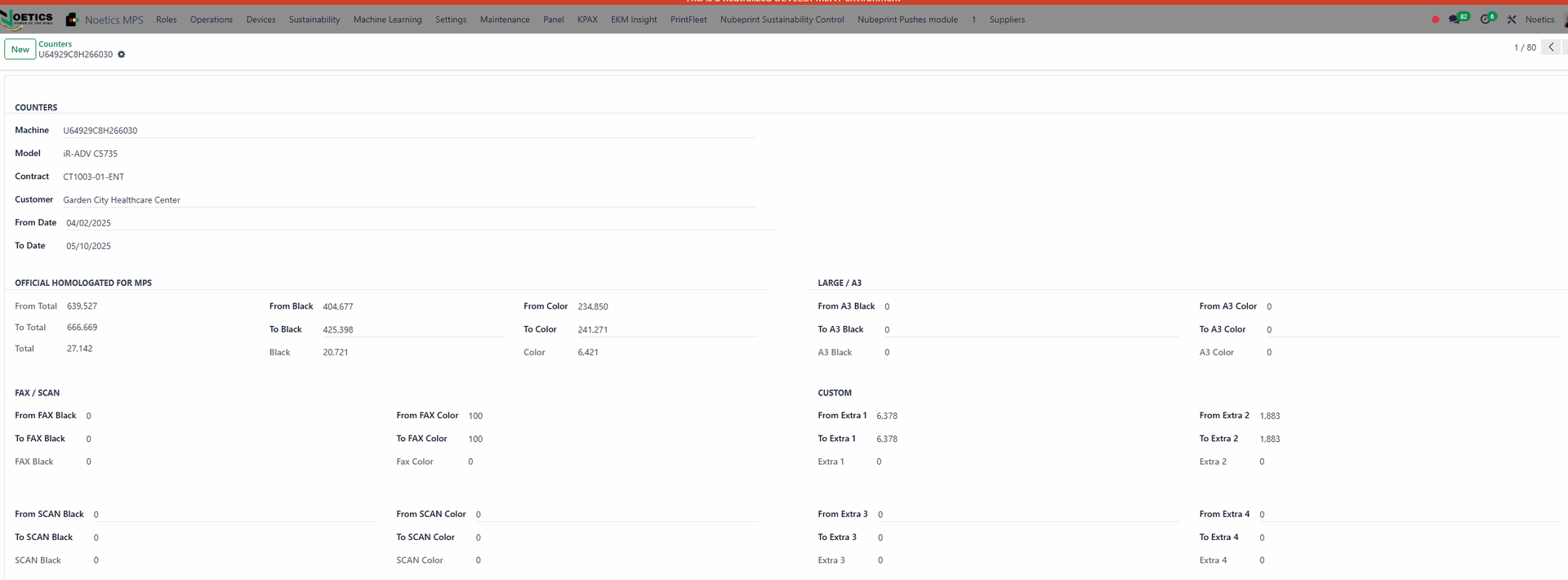

There is also MPS > Operations > Counters to allow a more organized view of meters collected:

Yes. The built in Noetics DCA agent is open source, and its full source code is included with every installation. This makes it 100% auditable. Users can extract the code by renaming the CPM executable (e.g., cpm.exe) to a .zip file and decompressing it, allowing full inspection of how the agent operates and what data it transmits.

- Install or extract the CPM .msi package.

- Locate the executable file (cpm.exe or monitor-silent.exe).

- Rename it to .zip (e.g., cpm.exe.zip).

-

Decompress it using any standard archive tool.

This will give you access to the agent’s source code and internal structure.

No. DCA does not run as a persistent background service. It is only launched manually or by the Windows Task Scheduler and does not remain resident in memory. This design eliminates common security vulnerabilities associated with always-on services.

The Noetics DCA is not installed as a Windows service. Instead, it is run as a Scheduled Task. It only consumes resources when it is actively running, which improves security and reduces system impact.

Data is transmitted over either HTTPS (port 443) or HTTP (port 80), depending on how the user configures it. HTTPS ensures secure, encrypted transmission, while HTTP allows for full visibility and auditability of the data being sent.

Yes. By configuring the Noetics DCA to use HTTP, all transmitted data is visible in plain text. This allows users to inspect the traffic and verify exactly what is being sent — including its content, origin, and destination — for full transparency.

No inbound ports need to be opened. The Noetics DCA only uses outbound ports 80 (HTTP) and 443 (HTTPS) for transmission, which are standard and typically already open on firewalls.

All data is transmitted to a fixed processing server over the internet. The server has a known, public IP address, allowing for controlled and auditable network behavior.

Yes. The Noetics DCA is designed to meet stringent security and compliance requirements, including:

- HIPAA (Healthcare)

- SOX (Financial transparency)

- GLBA (Financial data privacy)

- FISMA (Federal information security)

- ENISA (EU cybersecurity directives)

- RFCs for communication and data transmission protocols

This makes it suitable for use in healthcare, finance, military, and government sectors.

No. The Noetics DCA is a read-only, non-invasive tool. It does not require printer configuration changes, does not install as a service, and does not push drivers or updates. It only uses SNMP in read-only mode to gather data.

If a list of IP addresses is not provided, the DCA performs automatic discovery across the network using SNMP. This process is designed to be slow and efficient to avoid consuming bandwidth or disrupting devices. Discovery can be accelerated if printer IPs are known and preloaded.

Yes. The DCA supports complex network topologies, including segmented VLANs and WANs. It can be deployed on central or subnet-specific servers, and multiple CPMs can be used to cover different network segments. It works without requiring changes to network routes, printer ports, or firewall settings.

A machine refers to any hardware device deployed at a customer site that is tracked, serviced, and billed under a service contract. These devices are typically printers, copiers, or specialized equipment such as EMAR units or large-format printers (LFPs). As part of a Managed Print Services (MPS) program, machines are monitored for usage (meter counts), consumable levels (e.g., toner, drums), service alerts (technical faults), and online/offline status.

In Noetics, machines can be managed under various billing models and are either monitored automatically via a Data Collection Agent (DCA) or updated manually if unmonitored. Each machine record exposes operational data such as serial number, model, meter readings, status messages, and consumable levels, all of which support automated service, billing, and supply workflows.

In Noetics, a machine refers to a structured record representing a device on a service contract.

Each machine record typically includes:

- Serial Number – the unique ID of the device

- Model – The actual model of the machine. Can be set to "Discover" and updated automatically via DCA

- Status – e.g., Installed, Not Installed

- Class – NET, NETLESS, or LOCAL, depending on monitoring setup

They serve as the foundational unit for metering, invoicing, consumables, and service workflows in the Noetics MPS system.

Machines can be created in three ways:

Automatically via DCA Discovery

When a DCA scans a network (with proper setup), our system can:

- Automatically detect machines

- Match them to the correct contract

- Record key details like model, variant, and serial number

- Begin monitoring immediately

Manually via Excel Import or UI Entry

You can manually add machines by:

- Importing them through Excel

- Entering them in the UI under MPS > Contracts > Equipment on Contract

Automatically Upon Equipment Delivery

When a piece of equipment is delivered, Noetics will:

- Automatically create the machine record under Equipment on Contract

- Set its initial status to NOT INSTALLED

- Mark it as NETLESS (not yet monitored by a DCA)

- If this machine is going to be monitored by a DCA, mark it as NET so the first time the DCA will know to update the machine

- Set the model to Discover (placeholder until DCA picks up actual model when machine is set to NET)

Key fields like:

- Key operator information

- Machine location information

- Billing rates, allowances

- Maintenance and lease charges (if applicable)

…will be auto-filled.

Once the DCA detects the machine for the first time, the system will:

- Change the status to INSTALLED

- Update the model to what was actually discovered

This flow significantly reduces manual data entry and backoffice workload.

A consumable refers to any replaceable component in a printer or copier that is used up through normal operation. Common examples include:

- Toner cartridges

- Drums

- Waste containers

- Maintenance kits

- Fuser units

Each consumable typically contains a chip or sensor that reports its current status. This information, such as remaining life or usage level, is made available via SNMP and read by a Data Collection Agent (DCA).

However, the quality and granularity of data provided by each consumable can vary significantly depending on:

- The manufacturer

- The firmware of the printer

- The chip resolution in the consumable itself

If a consumable doesn't show a level at all, it typically means the device's chip doesn't expose the information or the monitoring tool (DCA) cannot read it. Using a Noetics DCA is recommended for full visibility.

In Noetics, consumables are tightly integrated with machine monitoring and supply automation. Each consumable is:

- Linked to a specific machine

- Automatically monitored if the machine is DCA-enabled

For each model that is read by DCAs and sent to your Noetics system we will auto populate all OEM consumables that go for that model, and you just have to choose which ones you want to keep and set the pricing

If we want to manually make a consumable in the system, we can go to Inventory > Products > Products and start making a new part where the key fields are:

- Product Name

- SKU/Part Number

- Consumable needs to be checked if the item is consumable

- Product Category needs to be Consumables

- Product Template Tags - need to list each model that this consumable would be used on

Key features of consumable management in Noetics include threshold-based automation, manual override options, and intelligent handling of low-resolution data. Each consumable has a configurable threshold, commonly set to levels like 20%, that determines when action should be taken. When a monitored machine's consumable falls below the defined threshold, Noetics can automatically generate a consumable order, create an inventory transfer and shipping confirmation and even a purchase order if you don't have that part in stock. In addition to automated workflows, the system also supports manual overrides, allowing users or customers to place consumable orders directly when needed.

This tight integration ensures that consumables are proactively replenished, helping reduce downtime and improving overall fleet efficiency.

A contract is a formal agreement between a service provider and a customer that defines how printing devices will be monitored, serviced, billed, and supported. These contracts often outline key terms such as monthly allowances (number of pages included), overage charges, consumable coverage, lease costs, service response times, and renewal conditions. Contracts may vary by customer, location, or machine group, and typically support different billing models, such as cost-per-page or all-inclusive leasing.

In Noetics, a contract is a structured digital record that links a customer to a group of machines and determines how those machines are monitored, billed, and serviced. Contracts are created under MPS > Contracts and contain fields for contract profile, duration in months, tags, sales channel, and customer assignment. Every contract starts in PILOT mode, which serves as a staging area where machines discovered by a DCA are collected for review. PILOT contracts are safe zones: they do not generate invoices, service alerts, or consumable orders.

Once a machine is confirmed as actively managed, the contract is duplicated and converted to ENTERPRISE. This transition enables the full billing lifecycle, including invoice generation, alerting, and consumable automation. The standard naming convention appends “-ENT” to the new contract for clarity. Contracts can be associated with one or more DCAs, which push discovered devices into the PILOT automatically. This two-phase model allows teams to separate discovery from billing, ensuring that only validated machines are included in active service and invoicing. Changing the contract type directly affects system behavior, making contracts a central and dynamic control point for service delivery.

MIF, or Machines in Field, refers to the full set of printing devices that have been delivered to a customer and entered into the system for tracking and management. In the Managed Print Services (MPS) industry, MIF represents all machines currently deployed at customer sites, regardless of whether they are under an active service contract.

These machines may be monitored, serviced, or billed depending on their configuration, but the core idea is that they are physically in the field and recognized in the system. MIF includes both managed and unmanaged devices, and is often used to measure total fleet size, onboarding status, and growth opportunities.

In Noetics, Machines in Field are recorded in the Machines on Contract section under MPS > Contracts.

Devices enter the system in two primary ways:

- Automatically detected by a DCA (Data Collection Agent), which discovers all printers on the customer’s network and adds them to a PILOT contract.

- Automatically created during the delivery process, when a machine is confirmed as delivered and assigned to a contract through Noetics automation.

Once in the system, these machines can be reviewed, classified, and moved as needed. Machines that remain in the PILOT contract are considered “unmanaged” for billing purposes, while those that are reviewed and moved into an ENTERPRISE contract make up the Managed Install Base. Meters for machines in PILOT contract will still be collected.

The Noetics Panel is a web-based dashboard used by customers and dealers to manage their printers in real time. It allows users to view active devices, enter manual counters (e.g., for NETLESS machines), manage alerts, configure email notifications, and group consumable shipments.

The Panel is also used to customize screen views, define shipment schedules, and monitor devices based on criteria like activity, threshold status, and assigned projects. It works alongside Cloud tools to support billing, visibility, and service workflows.

Once a machine becomes part of a contract it will get its own micro site that allows both the customer and the dealer to see and manage details of that machine.

Yes, temporarily. The Panel can be redirected to a test environment for a defined period during the testing phase. This allows safe simulation of actions like meter entry or service request submission without impacting production data. The switch can be reversed on go-live day to restore normal operations.

- INSTALLED: Machine is active and will trigger billing, consumables, and alerts.

- NOT INSTALLED: Machine is visible but will not trigger service actions. Used for onboarding or contract changes.

- RETIRED: Machine is hidden from the system and no longer managed or monitored.

- LOCAL: Partially monitored machines (e.g., USB-connected) where data is estimated.

- NET: Network-connected machines.

- NETLESS: Not connected to a DCA or SNMP tools. Data (meters, errors) must be entered manually via the Cloud.

Machines marked as NET or LOCAL but not actually monitored should be reclassified as NETLESS to ensure proper manual management.

Although machines are typically added to contracts automatically through delivery confirmation or DCA detection, you can still add a machine manually if needed.

To do so, navigate to: MPS > Contracts > Machines on Contract > New

When adding a machine manually, be sure to set the Class to NETLESS if the machine is not monitored by a DCA. This ensures the system knows it must rely on manual counter entry and management for that machine.

When manually creating a machine, use Model = "Discover" and set the Status = Not Installed. This allows the DCA to automatically detect and assign the correct model when it first reads the machine.

If the machine is NETLESS (not monitored by DCA), and your exact model isn’t showing, enter the most similar model manually (e.g., use “Bizhub 328” even if your device is “Bizhub 328e”). The system identifies models based on:

- The consumables they use

- The sensor stack and internal architecture

Minor external differences (like touchscreen size or network card count) do not affect model classification in the MPS logic. For example:

- "e" in Bizhub 328e (enhanced version) does not affect its base classification

- "n" in HP models refers to networking but has no MPS impact

Use the closest internal match available and continue setup.

To retire a machine, go to MPS > Contracts > Machines on Contract, search for the machine’s serial number, and update its status to RETIRED. You should also set the Retired Date to reflect when the machine was officially retired.

A machine is considered offline when it stops communicating with the system through its assigned Data Collection Agent (DCA), such as CPM. This usually means the device is no longer reporting data—like meter reads or consumable levels—due to being powered off, disconnected from the network, or blocked by configuration issues. Offline machines are not being actively monitored and may miss key alerts, supply orders, or billing updates. In Noetics you can adjust for how many days the machine should not report before it is marked as offline.

Our system can automate communication with the key operator on each machine via email and/or SMS to ensure the machine gets back on the DCA.

In Noetics, offline machines are automatically detected by checking the last reading timestamp from the DCA. Devices that haven’t reported within the defined offline threshold (measured in hours) are considered offline and are highlighted in red in the system. You can view these machines by navigating to MPS > Devices > Device Status and selecting the “Offline” filter. The exact time of the last update is shown per machine, and no manual action is required—when the machine comes back online, the system updates its status automatically.

Yes. Go to MPS > Devices > Device Status, open the serial, and in the Management tab set the Offline Threshold (Hours) value to the desired time frame.

The onboarding process for DCA specific-integrated customers follows this sequence:

- Import customer records

- Create two contracts per customer: one PILOT and one ENTERPRISE. The PILOT is used for unmanaged machines and onboarding, while the ENTERPRISE triggers billing and service.

- Import DCAs: Each active contract should have an assigned DCA (e.g., CPM or EKM), and machines detected by the DCA will be populated into the PILOT contract. From there, dealers move the managed machines into the ENTERPRISE contract.

Once DCAs are imported and linked to contracts, printers are automatically discovered and populated into the associated PILOT contract. These machines then begin reporting data and are considered online. Dealers can then move managed printers to the ENTERPRISE contract for billing and service activation.

Only for Nubeprint CPM (Noetics native DCA). After importing DCA records (e.g., CPM entries) via Excel, you can select all the created records in MPS > Devices > DCAs and use the “Request License” action to generate licenses in bulk.

Not directly. The DCA connector assigns machines to the default contract tied to that DCA. Adding logic to reassign based on DCA status like “Fully Enabled” would create performance issues. Instead, it's recommended to export a report from the DCA showing device status and manually reassign machines using a bulk import or interface tool in Noetics.

While this data exists in the DCA, syncing it automatically via API would overwrite any user updates made in Noetics or through the customer-facing PANEL. To avoid unintentionally erasing local edits, it's recommended to import location or operator data once during onboarding and maintain it manually afterward.

The preferred approach is a DCA-first process. This means importing customers and contracts (including both Pilot and Enterprise types), then assigning a DCA to the Pilot contract. The DCA will scan the network and automatically create machine records. Afterward, static data (like install date and billing rates) is enriched through Excel import. This method is faster, more accurate, and provides a better audit trail than manually loading all machine data upfront.

Machines that are not found in the DCA but were imported should be reviewed with the dealer. If they belong to terminated contracts, they should be marked as RETIRED. If they are no longer monitored, consider updating their class to NETLESS so they can be manually managed through the Cloud interface.

When a machine is loaded with Model = Discover and Status = NOT INSTALLED, the system waits for a DCA read. Upon first read, the correct model is assigned. Once assigned, the machine can be switched to INSTALLED and invoicing/alerts will begin.

There is a distinction between migration and operational processes. For one-time data migrations, efficiency matters more than best practices. Use the standard import template in MPS > Contracts > Machines on Contract to load rates and contract values.

For day-to-day operations after go-live, dealers should be trained on optimal workflows for updating rates and contracts directly in the system, as these are more consistent and error-proof than ad hoc imports.

When delivering a machine, the system may ask if you want to send DCA installation instructions to the customer. Click "Yes" only if you're using NubePrint CPM DCA and want the customer to receive instructions. If you’re using another DCA (like EKM or PrintFleet), always select "No."

If we say yes the system will connect a NubePrint CPM DCA license to a contract and send the download link for our DCA with the license to the customer.

A contract invoice in Noetics is a billing document generated based on meter readings and pricing rules set on machines under Enterprise contracts. These invoices are created monthly in DRAFT state, allowing the accounting team to review and send them individually or in bulk. Invoices are visible in our built in customer portal and you can take payment directly in the system via CC or ACH using our built in fintech solution.

Invoicing is triggered automatically if the customer has “Auto Invoice” enabled and an Invoice Cycle date set. The system calculates charges using current meter data and contract terms, including proration for machines added mid-cycle. Devices in Pilot contracts are excluded from invoicing. Manual invoice generation is also supported and can be used on it's own or paired with automation.

- Go to Contacts > Customers > Open the customer > Sales & Purchase tab

- Enable Auto Invoice

- Set the billing day of the month in the Invoice Cycle field

- Go to MPS > Contracts > Machines on Contract > Pick a Machine

- On the Installation tab ensure printer is in INSTALLED status

- Go to the Invoicing tab

-

Choose a Minimum type mode:

- NONE: bill actual usage

- COMBINED: a single covered copy for all meters combined

- SEPARATED: separate covered copies for B\W and color

- Choose an Invoicing group per machine

- STANDALONE: bill separate base and overage rate for this machine

- GROUP#:

- If all meters for all machines are in one group and share covered copies (B\W and Color separately), this will be GROUP1

- If there are multiple groups sharing different copies and rates, choose GROUP2, GROUP3, up to GROUP10 for the number of groups on the contract

- Set Covered copies and rates per machine

- If there is a group of machines sharing covered copies, choose one machine to carry the copies for the group and set the rest of the machines to 0

- (Black or Color) Price over minimum would be your rate over the covered copies.

- Minimum (Black or Color) copies would be the covered copies for the corresponding meter type

- (Black or Color) Price under minimum would normally be 0 unless you bill minimum copies vs a base

- Add up to 5 fixed-cost items under the Monthly Flat Fees section on the right

- Maintenance: This is normally the base rate on the contract.

- Monitoring: This was originally meant to bill for DCA monitoring, but can be used as another field for a base in the instance that you want to setup meter group base rates as opposed to Contract or equipment base rates (ea terms).

- Leasing: This would be for internal leasing or if you bill the lease and pay the leasing company (opposite of pass thru from the leasing company).

- Other 1: This is a misc charge.

- Other 2: This is a misc charge.

If a printer is active only part of the month, some costs are automatically prorated based on the Install Date or Contract Start Date (whichever is later).

- Maintenance, Monitoring, and Leasing fields are prorated

- Other 1 and Other 2 are NOT prorated

- Go to: MPS > Contracts > Machines on Contract

- Open a machine > Installation tab > Check the Install Date

- Ensure the printer is INSTALLED

- Confirm the Install Date — billing will begin from this date, or from the Contract Start Date if it’s more recent

There are two methods:

- Automatic: If Auto Invoice is enabled, the system generates billing reports and sends them via email on the set day.

-

Manual:

- Go to MPS > Roles > Customers (see "How can I manually invoice?" section below)

Automated invoicing is configured by going to Contacts > Pick a Customer, then navigating to the Sales & Purchase tab and enabling the "Auto Invoice" checkbox. You’ll also set the Invoice Cycle, which determines the day of the month when invoices are generated. The system will automatically gather meter readings from ENTERPRISE contracts on that day and generate a draft invoice with all calculations included.

The system also supports proration. For example, if a contract begins on 01/01 and billing is set to the 1st of the month, but a $300 maintenance machine is added on 01/15, the system will only bill $150 for that cycle, matching the active period.

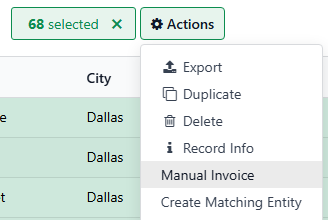

You can manually generate invoices for a customer using the manual invoice wizard.

Steps to manually invoice:

- Go to MPS > Roles > Customers.

- Find and select the customer.

- A new option will appear above your customer list

- Click Actions > Manual Invoice

You’ll see a popup where you choose how to process the invoice:

-

Only meters:

This option pulls meter data (initial, final, page type) and stores it in Operations > Counters. It’s useful for reporting or preparing to invoice. Be sure to set the "To Date" to today and click Invoice. -

Only invoice:

This option uses stored meter data and applies billing logic (groups, minimums, overages, etc.). It generates a billing report in Contracts > Contract Usage, which will automatically sync to Accounting > Customers > Invoices or can be pushed manually. -

All:

Runs both steps above — pulls the meters and generates the invoice. This is the standard option for live environments.

Important notes:

- Meter reads can be pulled from any contract (PILOT or ENTERPRISE).

- To generate actual invoices, machines must be on ENTERPRISE contracts. The wizard only invoices machines on active Enterprise contracts.

- If “Auto Invoice” is enabled and a billing cycle is defined on the customer, the system will run these steps for you automatically and generate a draft invoice in Accounting.

If an invoice was created using incorrect pricing (e.g., a wrong per-page rate was entered in the Invoicing tab):

- Delete the invoice in the Noetics Billing module.

- Correct the rates on the machine or contract record.

- Return to the customer record and use the Manual Invoice action to regenerate the invoice.

There’s no need to change the meter values or the last invoiced date. The system will use the existing meter data for the new invoice.

If the mistake was in the meter values used during invoicing:

- First, delete the invoice — this is required to unlock the meter records.

- Go to Operations > Counters and delete the incorrect meter entries.

- Once removed, the system will automatically update the last invoiced date and allow you to re-enter the correct values.

- Return to the customer and regenerate the invoice using the Manual Invoice action.

- You must delete the invoice first before deleting any associated meters.

- You can only delete the most recent meter readings. Older readings cannot be removed if newer ones exist, to preserve the meter evolution logic.

Yes. Dealers can combine equipment lease charges and MPS service fees into a single invoice. This is done by populating values in the "Monthly Flat Fees" fields on machine records. The system picks up those values and includes them in the generated invoice, aligning with the one-invoice model preferred by some dealers.

Yes, in Noetics you can maintain your in-house leasing company. If you share the CoA or have a totally separate one, we can maintain both in one database and control access, reporting and functions independently.

Lease costs can be handled in two ways:

- Option A: Assign the full lease cost to a single “master” machine in the group.

- Option B: Prorate the lease amount across all machines in the contract. This method is ideal for contracts where the install base may change over time.

The lease cost is then added to the invoice using the Leasing field and prorated automatically based on billing cycle duration.

These are customizable charge fields used to pass through flat monthly costs that we don't want to prorate. Think of it as miscellaneous charges

They appear on the invoice under labels that can be renamed to match your preferred billing language.

These values are not prorated and will always bill a fixed number.

If each location is treated as a separate customer (which is often the case in ERP systems), then the recommended approach is to create a separate contract and customer record per location. Machines discovered by the DCA can be assigned to the appropriate contract, and the customer address will auto-populate at the printer level. This also ensures that each location gets its own invoice.

Alternatively, if all locations fall under a single customer, users can manually update the Company and Location fields on each machine. This allows the same customer record to reflect different physical locations.

There are two ways to handle this scenario:

Option 1:

Treat each location as a separate customer in the system. Each will have its own contract, making it easy to manage location-specific billing and movement of machines. The company name and location will update automatically when a machine is reassigned.

Note: This approach will generate separate invoices per location since each is treated as a distinct customer.

Option 2 (Preferred):

Keep everything under a single customer record to streamline billing. Reflect different company/location names by:

- Updating the Company Name on each Equipment record

- Manually adjusting the Location fields

This lets you manage multiple locations under one billing account. For bulk changes, export and re-import the following fields using Excel:

- External ID

- Serial Number

- Model

- Variant

- Company

- All Location fields

This method helps ensure accurate install details while minimizing contract clutter.

If a machine was skipped due to missing meters or other issues, don’t worry. If you enter the meters after billing, the system will automatically include the usage in the next billing cycle. Alternatively, you can manually trigger an invoice to catch up the missed charges.

Invoices will not generate if the contract is of type PILOT. PILOT contracts are non-billable by design—they allow monitoring and setup but do not support invoice generation. To enable invoicing, machines must be moved to an ENTERPRISE contract.

The system calculates Black pages as Total minus Color. If the Color count exceeds the Total, it results in a negative value, which is invalid. In such cases, the system blocks invoicing to avoid incorrect billing. Ensure that the Color counter is equal to or less than the Total counter.

Yes, you can manually enter counters via Open Cloud and attempt to trigger invoicing using the “Only Invoice” button. However, this only works if the machine is under a billable (ENTERPRISE) contract. Also, this workflow does not function in test databases unless specific configurations are enabled—otherwise, it may affect production-linked data.

Allowance refers to the amount of usage—typically the number of printed pages—included in a customer's contract at no extra charge. Allowances are usually defined per billing cycle and may apply to black & white pages, color pages, or both. In Noetics, an allowance is set at the machine or group level and defines the minimum included volume before overage charges apply. The system can calculate this per device or by aggregating the total across a group of machines. Allowances help automate billing and ensure customers are only charged for usage beyond what their contract includes.

Yes. If multiple machines (e.g., black & white printers) are part of the same contract, their meters can be billed together using a shared group allowance. You would assign both machines to the same group (e.g., “Group1”) and set their invoicing method to combined. This allows their usage to be calculated collectively.

There are two ways to handle the allowance:

- You can define equal minimums per machine (e.g., 3,750 on each machine to total 7,500).

- Or define the full allowance on one machine (e.g., 7,500 on one, 0 on others). In this case, you must manually update the total if new machines are added to the group.

Yes. You can group machines for black meters only, while leaving color meters billed separately. For example, in a 3-machine setup, you could set a shared black allowance for Group1 and assign 0 allowance for color, which would then be billed independently per machine.

No. In the current system, each machine can only belong to one billing group, and that group defines the pricing logic for both black and color meters. Unlike some other platforms, dual group assignment is not supported.

CPI stands for Cost Per Impression (or Cost Per Image) and refers to the price charged for each printed page. In Managed Print Services (MPS), CPI is used to calculate billing based on actual usage, either for black & white or color pages. In Noetics, CPI is defined on each machine record under the Invoicing tab as:

-

BW CPI

- Color CPI

Overages refer to the amount of printer usage—typically measured in pages—that exceeds the base allowance included in a customer’s contract. For example, if a contract includes 5,000 black pages per month and a machine records 6,200 pages, the extra 1,200 pages are considered overages and are billed at the configured per-page rate.

In Noetics, overages are calculated automatically when a machine’s usage goes beyond the set threshold defined in its pricing setup. The system applies the configured "Price over minimum" (black and/or color) to the excess volume, and this is reflected in the contract invoice during the billing cycle. Overages only apply when an allowance is present and separated from flat-fee billing.

Minimum types define how allowances are set for each machine on a contract. You have three options:

1. Separated

- Define separate allowances for Black & White and Color copies

- Ideal when you want to bill or track each type independently

2. Combined

- Set a single total allowance that includes both Black & White and Color copies

- No need to distinguish between the two in billing or reporting

3. None

- No minimum allowance is set for the machine

- All usage is billed as overage

Book pricing refers to the default or list price set for products, services, or page rates before any discounts, custom agreements, or overrides are applied. Book pricing serves as the baseline for quoting and billing, and is often stored in a central pricing catalog or rate table. Dealers may adjust this pricing per customer, per contract, or during negotiation—so the book price is essentially the "starting point."

A lease refers to a monthly payment agreement between a dealer (or leasing provider) and a customer for the use of printing equipment. Instead of purchasing devices outright, customers pay a fixed monthly fee over a set term (commonly 36–60 months), allowing them to access hardware without large upfront costs. This leasing model often works alongside a separate service agreement for maintenance, consumables, and support.

There are two types of billing approaches when it comes to leasing:

- Bundled - The dealer will bill for the lease payment on their monthly contract invoice and then on a agreed-upon cadence. Remit the collected funds to the leasing company

- Traditional - The customer will receive a invoice from the leasing company for the lease payment and the dealer will bill for their service as per the contract

Once the equipment is delivered, the dealer is to send an invoice to the leasing company for the full value of the equipment to collect the payment

In Noetics, based on the configuration on the sales order our system will auto fill the lease payment per machine so that when invoices go out it includes the lease payment (for bundled billing)

Once a deal is signed our system will do all the calculation and setup a lease record in the system for you that is connected to the contract and the sales order.

Pass-through service means that when we sell a piece of equipment with service included and we mark it as Pass Through service, the service will be a line on the lease because we want to bill the leasing company for that service rather than the customer.

A rate card is a table that defines the cost structure for leasing equipment based on:

- Lease term lengths (e.g., 24, 36, 48, 60 months)

- Purchase options (e.g., Fair Market Value, $1 Buyout)

- Price ranges of the deal (e.g., $25,000–$49,999)

- Rate factors used to calculate monthly payments

You multiply the deal value by the rate factor from the card to get the monthly lease payment. Rate cards are provided by leasing companies to standardize and automate lease pricing.

A rate factor is a decimal used to calculate the monthly lease payment for a deal. Common in leasing, it simplifies payment calculations. For example, a $10,000 device with a 0.020 rate factor results in a $200 monthly lease. Rate factors are typically provided by leasing companies and are used to structure customer payment plans.

Purchase options are the choices a customer has at the end of a lease agreement for their equipment. These options may include purchasing the equipment at its fair market value (FMV), completing a $1 buyout to take full ownership, upgrading to new equipment, or simply returning the device with no further obligation. The specific options available are defined in the original lease agreement and provide flexibility based on the customer’s needs at the end of the contract term.

Lease terms are the lengths of time (in months) that a lease agreement lasts. For example:

- 36 = 36 months = 3 years

- 60 = 60 months = 5 years

- 69 = 69 months = 5 years and 9 months

These terms define how long the customer will make payments before the lease ends. The term you choose affects the monthly payment:

- Shorter terms (like 24 or 36) usually mean higher monthly payments.

- Longer terms (like 60 or 69) reduce the monthly cost but extend the obligation.

Leasing companies offer different terms to give customers flexibility based on their budget and how long they plan to keep the equipment.

A credit application is a form submitted to request financing or leasing approval for equipment. It provides the leasing provider with the customer’s financial and business details to assess risk and determine eligibility. Approval is typically required before entering into a lease agreement or financing plan for MPS equipment. In our system when a credit application is submitted that will also make a lease in a pending approval state - when the credit application goes to Booked, the lease will be moved to active.

In the Managed Print Services (MPS) industry, maintenance, service, or base refers to a recurring charge that covers the essential support and upkeep of a customer’s printing devices. This includes services like preventive maintenance, technical support, dispatch for repairs, and sometimes a base volume of included pages. It's a fixed fee billed regardless of usage and forms the foundation of most service contracts. Depending on the agreement, this charge may be billed separately or grouped with leasing on a single invoice.

In Noetics, the maintenance or base charge is managed as part of the contract invoice cycle, but only for machines under ENTERPRISE contracts. PILOT contracts do not trigger billing, including service charges. Maintenance charges can be set per machine, or assigned to a master device in a group.

Base charges can be added to the invoice using defined fields and are tracked within the Invoicing tab on each machine record. Noetics also supports proration, so if a machine is added partway through a billing cycle, the base charge is automatically adjusted based on the number of active days.

Yes. Annual contract escalation is supported and allows dealers to automatically increase CPI (cost per impression) rates, overage charges, and maintenance fees each year based on the contract’s start date. Escalations can be configured either system-wide (for all contracts) or per contract, with separate percentages for each charge type and for each year—up to seven years.

The system uses a daily automation process to check active contracts and apply the correct increases each year. Proration, contract types, and machine-level billing settings are respected, ensuring that escalations apply only where intended. This helps dealers keep pricing aligned with inflation, rising costs, or long-term agreement terms—all without manual updates.

An EMAR (Electronic Medication Administration Record) machine is a specialized device used in healthcare environments, typically powered by a generator and only active during emergencies. These machines can be part of broader contracts but may require unique billing rules because they are intermittently powered on.

In such cases, base (maintenance) fees may be billed monthly, while overages are billed quarterly.

“Toner Only” machines are those for which only toner is included in the service contract—other consumables like drums or fusers are excluded.

To configure:

- Turn OFF thresholds for excluded consumables (e.g., drum, fuser) in the machine record.

- Use % thresholds (not days remaining) to trigger toner-only alerts and orders.

- “All Inclusive” machines will have all relevant thresholds active for full monitoring and supply fulfillment.

The "Machines Managed" count on a contract shows all machines linked to that contract, regardless of their current status (e.g., Installed, Not Installed, Retired). This count is not automatically filtered based on activity status.

If you want to see only active or billing-eligible devices, you can use the saved filters at the top of the view — such as:

- "Active" – shows machines that are Installed

- "Pending" – shows machines that are Not Installed

To ensure that inactive machines (like those marked as Retired) don’t clutter your view or get miscounted in billing prep:

- Mark the machine’s status as Retired under MPS> Contracts > Machines on Contract — this removes it from billing eligibility.

- When viewing "Machines Managed" from a contract, use the "Active" filter to see only Installed machines or the "Pending" filter to view Not Installed machines.

- To get a full picture of all non-retired machines, you can combine both filters or create a custom one that includes both Installed and Not Installed statuses, while excluding Retired.

A sublease, as referred to by dealers, typically means adding a new piece of equipment to an existing lease agreement so that the customer continues to receive a single monthly lease invoice. This is not a formal sublease in legal terms, but rather a consolidation of payments for multiple leased devices into one invoice.

A coterminous lease aligns the new lease with the remaining term of the original lease. In practice, this means:

- The leasing company offers a reduced term (e.g., 50 months instead of 60) for the new device.

- The equipment is added to the master lease via a Schedule A document.

-

The system should reflect this by either:

- Adding the full lease value to a “master” printer, or

- Prorating lease costs across machines using designated fields (e.g., Lease Payment).

You can use the Lease Payment field to capture individual lease charges per machine. For example:

- Enter the full lease value on the master machine, and set all others to 0.

- Or spread the lease values across machines. The system will total these and include them in the invoice.

This setup supports multiple leases under a single invoice, with no extra configuration required from the customer side.

A consumable order is a request for toner, drums, or other printer supplies, triggered either automatically by the system or manually by users or customers. When a printer’s consumable levels drop below a configured threshold, and the machine is in INSTALLED status and assigned to an ENTERPRISE contract, Noetics will automatically generate a quote.

Consumable orders can also be created manually. Users can enter them directly in the system, or customers can request supplies through the printer’s micro site (only for NETLESS machines).

Consumable orders are handled through a combination of automation and user control. Machines monitored by a DCA are checked continuously against configured consumable thresholds. When a threshold is reached, the system automatically generates a Sales Order in the Sales application which then triggers downstream actions like creating all needed inventory transfers or purchase orders (if demand can't be met. Our system checks this in real time)

Orders are only generated for machines marked as INSTALLED and assigned to ENTERPRISE contracts. Machines in PILOT contracts or marked as NOT INSTALLED are excluded from automated order flows. Vendor selection for each machine can be configured under the Shipment tab in MPS > Contracts > Machines on Contract for each machine, allowing users to control how and where consumables are sourced.

Consumable catalogs in Noetics are organized lists of part numbers (SKUs) used to match supply alerts with the correct reference. Catalogs are grouped by origin—such as OEM, remanufacturer, or third-party vendor—and ensure that each device or customer receives the appropriate consumable, even if they don’t use OEM parts.

There are three catalog types:

- OEM: Preloaded, system-provided references. These cannot be modified. Will be added for you for every new model read by the DCA

- OEM-Zone: Vendor that provides you OEM consumables that are not the actual OEM

- Vendor: Alternative references. This is the highest-priority source for matching alerts.

Noetics follows a strict catalog hierarchy:

- First, it checks the Vendor catalog.

- If not found, it checks the Master catalog.

- If still not found, it defaults to the OEM catalog.

This ensures that the system always uses the correct SKU—even for third-party or mixed-brand environments.

Custom catalogs let you:

- Use third-party or remanufactured consumables.

- Assign different part numbers to the same model depending on the client.

-

Ensure alerts and supply orders are accurate—even with non-OEM consumables.

This reduces inventory errors, avoids confusion, and supports clients with cost-saving preferences.

Each dealer can have their own consumable catalog, which defines the specific toner, drum, or supply SKUs available for their machines. These catalogs are typically created from validated data files submitted by the dealer and must be carefully reviewed to avoid errors. Once finalized, the catalog is uploaded to the system and linked to the dealer’s environment.

If issues are found (e.g., missing product codes or duplicates), the catalog must go through a second validation round before being activated. Catalogs are customer-specific and drive what items are available for automatic and manual consumable orders.

Go to: MPS > Settings > Consumable Vendors

- Add a Name and Description

- Choose a Type: OEM (default, non-editable), Master, or Vendor

Catalogs follow a priority hierarchy that determines which reference is used first during alert generation.

Go to: MPS > Settings > Consumables

- For small quantities, manual entry is recommended.

- For large batches, use CSV or Excel import.

Each reference should include:

- Part Number

- Model

- Consumable Type

- Alias (optional)

- Vendor (must already exist)

- Description

- Durability

- Optional pricing fields

Do not upload SKUs already present in another catalog.

Go to: MPS > Roles > Customers > Settings tab inside the customer record

Under "Type of consumable", choose the preferred catalog. All devices under this customer will use this catalog for consumable alerts unless overridden at the device level.

Yes. Go to: MPS > Contracts > Machines on Contract > Select a machine > Shipment tab, and select the catalog under the “Vendor” field for that device.

This overrides the customer-level catalog only for that machine.

If a reference isn’t found in the assigned catalog, Noetics will automatically check the next catalog in the hierarchy (Vendor → Master → OEM) until a valid match is found. This guarantees that the alert will always point to a usable SKU.

Yes. For every product in your inventory, you can define minimum and maximum thresholds. These settings allow the system to either recommend or fully automate order creation when stock levels go below the defined minimum.

You can configure this in Inventory > Configuration > Reordering Rules.

Yes. Go to Contacts, find the customer, and under the Consumable Vendor tab select “OEM” (or any preferred vendor) for all machines.

Yes. Go to MPS > Contracts > Machines on Contract, locate the machine, and select the vendor you want to use from the Shipment tab.

A meter (or counter) measures the usage of a device—similar to how a car has an odometer or a home has a water meter. In printers, counters track pages printed, and they are used for billing and scheduled maintenance. Different printers may have various counters (e.g., total, black, color, scan, fax), but the most reliable is the motor cycle counter, also known as the MPS-compliant counter.

An MPS-compliant counter refers to the motor rotation counter, which is the only counter type that is consistent and comparable across all printer brands and models. It is the standard reference for billing, maintenance, and consumable lifespan in Noetics.

Different printers (and even the same printer) can report multiple counters, such as A3 vs. A4, color vs. black, or multiple regional units (miles vs. kilometers). Using the wrong one may lead to incorrect billing or maintenance cycles. The MPS-compliant counter ensures consistency and accuracy across devices and brands.

- Use the Counters App in the PANEL to view registered meters.

- The Cloud view for each printer also shows a histogram of monthly page volumes.

- For broader reporting (fleet, project, or client level), use the Charts App.

Noetics stores all meter readings for 12 months. After that, only the last meter record of each month is retained to preserve usage history while optimizing storage.

Yes. Customers can access the printer’s microsite and use the "Enter Counters" button to submit readings. This only works for NETLESS machines.

Yes. Go to MPS > Contracts > Machines on Contract, select the serial number, and click Open Cloud. From there, click Enter Counters and submit the meter reading. For color devices, enter both Total Counter and Color Counter — the system will calculate black automatically.

This function is available only for NETLESS machines ONLY.

Yes, importing historical meter readings by serial number is possible. You can prepare a list with the last invoiced meters and dates and upload it to update existing contracts. However, any discrepancies in invoice dates (e.g., off by one day) should be handled carefully during import to avoid confusion or duplication.

In addition to the default counters (e.g., Total, A3, Scan, Fax), you can register up to 4 custom counters per printer model. This is available based on your license type.

You can register extra counters yourself:

- Go to MPS> Settings > Custom SNMP

-

Click Create and enter:

- Alias: Display name

- Model: Printer model

- OID: SNMP path (starting with a dot)

- Object Code: Field where the data is stored (avoid overwriting standard fields)

- Partner: Optional (leave blank for global)

- Click Save — the DCA will collect this data in the next read cycle.

Yes. For machines classified as NETLESS (i.e., not connected to a monitoring platform like EKM), counters can be manually entered using the Cloud interface. This allows users to update meter readings for machines that aren’t being tracked automatically.

The "Enter Counters" option is only available for machines marked as NETLESS. If a machine was previously labeled as NET and recently changed to NETLESS, it may take time for the change to be fully registered by the system. If the feature doesn’t activate, ensure the classification has been saved and is recognized by the PANEL.

An OID (Object Identifier) is a technical path used by SNMP to locate specific data on a printer. When adding a custom counter, you must know the correct OID for the counter you want to track. You can obtain this from the printer manufacturer.

Yes. When setting up a custom counter, you can assign it to all partners or restrict it to a specific sales channel by selecting the Partner field.

Once saved, the new counter is immediately available across all monitored printers of that model. There's no need to update the DCA or visit customers.

A threshold is the defined point at which the system generates a warning or alert for a consumable. Traditionally, this is expressed as a percentage (e.g., 20% toner remaining), but in Noetics, you can also manage thresholds by remaining days.

Go to MPS > Device Reporting > Device Status, find the serial number, and open its detail view. There, you can adjust the threshold percentage for each consumable. The default is 20% — when this level is reached, the system automatically creates a supply order. You can set different thresholds per consumable and per machine.

Because percentage levels are not meaningful on their own. For example, 20% toner remaining may last 3 days on one printer and 3 weeks on another. Without context like device usage patterns, percentage-based alerts can lead to inefficient or mistimed consumable orders.

Day Management is a system that replaces percentage-based thresholds with remaining days. Instead of defining a low-percentage alert, you define how many days in advance you want to be warned before a consumable runs out. Noetics uses AI to calculate when that should occur based on actual device usage.

Our AI engine analyzes each device’s historical usage and current consumption rates to convert percentage levels into remaining days. The system dynamically adjusts thresholds to reflect real-time behavior, improving over time as usage patterns stabilize.

You can activate it through:

- PANEL: Go to Status App, click the indicator in the “Thresholds” column, and switch from percentage to days.

- ERP: Go to MPS > Device Reporting > Device Status > Open a device > Consumables tab, and change the threshold type from percentage to days.

Mass updates can be done through PANEL or via import/export in ERP.

The system will automatically fall back to percentage thresholds if it determines there is insufficient historical data (e.g., for printers that are not regularly used or newly added).

Yes. Noetics allows hybrid management. You can configure each machine individually to use either percentage or day-based thresholds, and switch between them at any time.

Yes. Both interfaces are fully synchronized. Mass updates are typically done in PANEL, while detailed, machine-specific adjustments are handled in ERP. Any change made in one is immediately reflected in the other.

A threshold is considered “at risk” when the number of days remaining is less than the alert margin. For example, if you set a 30-day threshold but the printer consumes a cartridge every 7 days, the system will flag that it's unlikely to meet the 30-day target with a single supply.

In PANEL, at-risk printers appear greyed out, and a banner is shown in ERP.

Technically, Day Management can be activated from day one, but it is recommended to wait at least one month to allow the system to collect enough historical data for accurate predictions.

Resolution refers to the granularity and accuracy of the level data that a printer provides for its consumables. Higher resolution means more precise information (e.g., small percentage steps), while lower resolution means coarser or limited data (e.g., only "OK" or "Empty").

- Null: No data is provided at all.

- Very Low: The consumable only reports two states — OK or Empty.

- Low: The level is reported in large increments (e.g., 25% steps), and thresholds below this are unreliable.

- Medium: Slightly better, but still reported in increments (e.g., 10% steps); thresholds below 10% are not reliable.

Noetics uses machine learning to transform low-resolution consumable data into high-resolution (granular) values. This ensures that all consumables appear with consistent and actionable level data, regardless of the printer model, chip type, or firmware.

- Check the Cloud Level graph: A smooth, continuous evolution indicates high resolution.

- In Data Monitoring, you'll see the raw (possibly low-resolution) level.

- In Status or Cloud, the level shown has been processed by Noetics and appears in high resolution if it was originally low.

No. If a printer already provides reliable high-resolution data, Noetics does not alter it. Only low-resolution data is transformed. This guarantees that all level data displayed in Noetics is coherent and easy to interpret across different brands and models.

VLS (Virtual Level Sensor) is a machine-learning–based system that estimates consumable levels when the printer does not report them. VLS allows consumables without readable status to be managed as if they were reporting their levels, enabling consistent alerting and analysis across all devices.

It means the system is estimating the consumable’s level using alternative data, like:

- Page volume

- Usage history

- Behavior of complementary consumables

- Other internal signals

This allows the system to provide estimated levels even when the printer itself does not report them.

In the Cloud interface, look at the VLS column:

- Blue dot = VLS is active and initialized

- Red dot = VLS is enabled but not initialized

- No dot = The consumable is not managed by VLS

Initialization is the process of providing a known, accurate starting point (e.g., 100% when installing a new cartridge) to improve the accuracy of VLS estimations. It significantly enhances the reliability of level calculations.

- Log into Panel

- Open the Cloud view for the printer

- Click the blue or red dot in the VLS column

- Enter the known level (e.g., 100% for a new install)

You can initialize at any time, but the best moment is immediately after installing a new consumable, when you know the level is 100%.

No. One initialization per printer is typically enough, but doing it more often (especially after installations) improves accuracy and is recommended when possible.

The system will still estimate the level, but with lower accuracy. Until initialization occurs, the system will not trigger alerts, even if the estimated level is low.

Yes. If the system detects reliable cues (like an on-screen message or related consumable status), it can auto-initialize the VLS. When this happens, the red dot changes to blue.

Alerts are proactive notifications that inform you when a consumable in a printer is approaching its threshold and needs to be replenished. Noetics monitors each consumable individually—regardless of whether the printer can report levels—and triggers alerts based on granular level data or estimated remaining days.

Once a consumable reaches the alert threshold, Noetics generates a single notification and waits until the cartridge is installed. Only after installation is confirmed does the system close the alert. This prevents repeat notifications and avoids accidental duplicate shipments.

If certain consumables aren’t monitored, downtime risks remain. To ensure full automation and efficiency, every consumable in every monitored printer should be tracked. If any consumables are missing from a model, you can request their addition via your Noetics representative.

There are two types of thresholds:

- Percentage-based thresholds (e.g., 20%)

- Day-based thresholds (e.g., 7 days remaining)

To modify percentage thresholds:

- Go to PANEL > Status App

- Click the Thresholds icon next to the printer and adjust the values

To modify day-based thresholds:

- Go to Status App

-

Either:

- Use “Activate threshold in days” to apply to all printers in the project

- Click the Thresholds icon next to an individual printer to set it manually

If a consumable provides no level data, Noetics activates Virtual Level Sensor (VLS) technology to estimate its remaining level. Alerts can then still be generated based on these estimations, using percentage or day thresholds.

- Open Inventory App

- Locate the printer and open the Cloud

- Look for red circles in the VLS column (unsynchronized consumables)

- Click the red icon and enter an estimated level (e.g., 100% at installation)

Synchronization significantly improves estimation quality and is usually only needed once per printer.

The Forecasts App displays your upcoming consumable needs. It’s especially useful when migrating to Noetics from a manual system (like Excel). After reconciliation, the Forecasts App becomes your main tool for predicting and managing future shipments.

- Begin monitoring contracts in Noetics.

- Freeze the Excel tracking file you were using.

-

For each alert:

- Check if you’ve already shipped the item via Excel.

- If not, ship and reconcile both in Excel and Noetics.

- Once all alerts are reconciled, stop using Excel.

- From then on, use Noetics and the Forecasts App exclusively.

A reliable system must:

- Monitor all consumables (even those without level reporting)

- Provide granular level data (not large % jumps)

- Estimate remaining days of usage per consumable

These features allow you to forecast accurately, reduce waste, and manage deliveries efficiently.

Yes. Noetics is not limited to its own monitoring agents. It can process and enrich data from any third-party DCA, allowing you to automate supply delivery, technical alerts, and billing without reinstalling agents on your customers' devices.

By connecting your existing DCA to Noetics, you can:

- Avoid reinstalling agents at each client site.

- Automate consumable delivery and dispatch scheduling.

- Identify client needs up to 90 days in advance.

- Eliminate duplicate shipments and reduce toner waste.

- Gain visibility into actual consumable performance.

- Reduce MPS contract costs by over 30% (when integrated with ERP).

- Request API access from your current monitoring tool provider.

- Share the API connection details with Noetics Support.

- Noetics will complete the activation process within 3 days.

- Contract in Monitoring Tool: Ensure printers are registered under an active contract.

- Create a Project in Noetics: Use the same name as in the monitoring tool.

- Open MPS > DCAs.

- In the DCA screen, change the Partner Number to match your monitoring system and linked contract.

- Validate the changes — printers will appear automatically in Noetics.

You must replicate the contract structure in Noetics and manually create each DCA record so that every contract in your monitoring tool has a corresponding DCA in Noetics.

If certain consumables don’t show levels, your current monitoring tool likely can’t read them. To resolve this, consider using a Noetics DCA for more complete monitoring coverage.

Printer updates depend on your monitoring tool. If printers appear offline in Noetics:

- Check their status in your monitoring tool.

- Perform any necessary refresh or sync actions there.

- Once updated, the printers will automatically update in Noetics as well.

Yes. If your monitoring tool isn’t listed in the connector dropdown, contact your Noetics representative. They may already be working on compatibility or can build the integration upon request.

As soon as the connection is made between Noetics and your monitoring tool for a customer, data is pulled immediately — no waiting period is required.

Check the following:

- Ensure the monitoring tool contract actually contains printers.

- Confirm you linked to the correct contract, not one with a similar name but no devices.

- Validate that the printers are actively being monitored in the source tool.

Grouped Shipments is a feature that allows you to schedule all consumable deliveries for selected printers on a specific day of the week. This improves logistics efficiency, reduces inventory waste, and supports sustainability by avoiding fragmented, last-minute deliveries.

There are three shipping logics that can be configured per printer:

- Ship Individually (Direct Delivery) – Consumables are dispatched immediately when needed.

- Customer Warehouse – Consumables are sent when the customer's warehouse stock drops below a set threshold.

- Group (Grouped Shipping) – Consumables are sent on a designated weekday, consolidating multiple shipments.

You can configure grouped shipments using either:

- PANEL (Basic) – Easily apply a shipping day across one or more projects.

- ERP (Advanced) – Configure shipping method and delivery day per printer with more flexibility. You can filter machines by criteria (e.g., location, model), then bulk update via export/import.

- Select one or more projects in the Grouped Shipping App.

- Use "Set Delivery Day" to define the weekday for all selected printers.

- Use "Set Delivery Method" to apply the Group logic if not already set.

Printers will only appear if they meet all three of the following conditions:

- Belong to the selected project

- Are managed using thresholds in days

- Are active, meaning they have recent print activity

Yes. You can modify the shipping method or delivery day at any time. The system automatically adapts and prioritizes avoiding printer downtime—without duplicating orders.

The system will attempt to respect your configured delivery day but will override it if waiting would cause a machine to run out of supplies. Common reasons include:

- The threshold will be reached before the scheduled shipping day

- A sudden spike in usage alters the forecast

In these cases, the system sends the alert early to prevent downtime.

A technical alert is a system-detected fault reported by a DCA-monitored printer, such as a damaged drum or other hardware issue. When registered by a DCA, Noetics automatically generates a service ticket in the Helpdesk/Dispatch module, where it can be reviewed and dispatched according to your workflow rules.

In addition to automatic alerts, customers can also request service manually through the printer’s micro site which will automatically put a ticket in for Noetics, they can email a inbox we would configure to automatically make a ticket for you in the system, or using our built in form on your new website connected to your Noetics ERP. Users can create tickets manually within the system as well, ensuring flexibility in how issues are reported and resolved, just in case you have customers that like to call.

The system will detect technical alerts and generate a service ticket automatically.

Customers can also request service manually through:

- The printer's mini website

- A form hosted on your website

- An email to a monitored inbox

- Or you can enter the request manually

When a technician pulls a part that’s not in their inventory, the system checks all other available locations (including other technician trunks). If it finds the part in another uncommitted location, it will generate the proper transfer and inventory documentation. If no stock is available, the system automatically creates a purchase order and related documents to procure the part.

Yes. When a service ticket is created, the system shows the serial number and the contract (if the machine is under one) directly on the service order. This helps techs quickly confirm whether the machine is covered